Machine park and production techniques

We have state-of-the-art, versatile machinery and use the latest production techniques and processes to meet your requirements.

Production process

We produce in 5 axis milling process, mill-turning, turning and by means of sheet metal production. Another core competence is multiple surface finishing and heat treatment. Our manufacturing techniques also include selective laser melting / metal sintering (SLM) of Inconel and titanium (3D metal printing) as well as all surface and heat treatment processes.

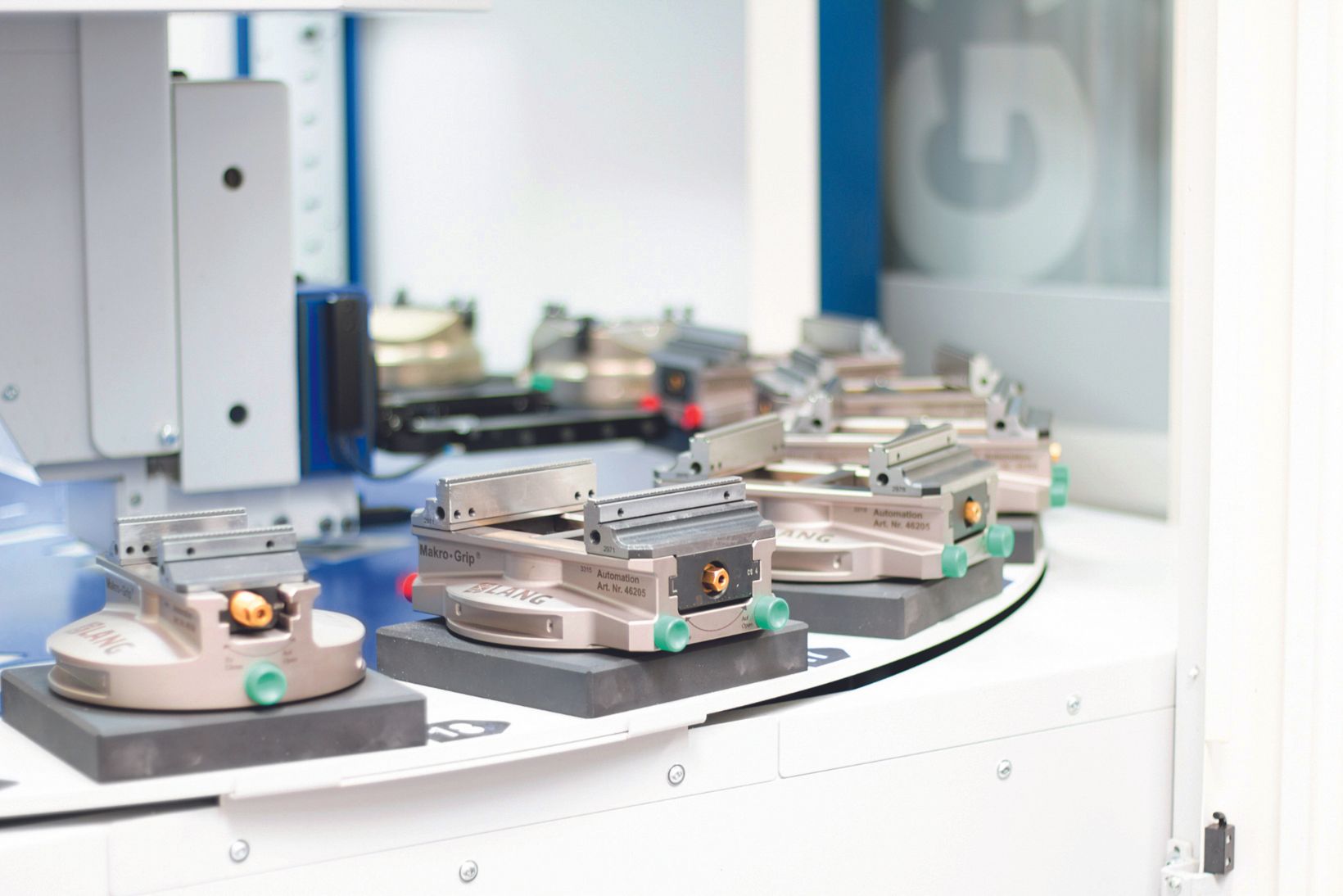

Machine park

Our machine park is configured for a wide range of work steps and manufacturing processes.

Our machine park

Milling:

- 5-axis milling machining center Grob G 350 Generation 2 with Automation Lang Ecocomopact 20 (component dimensions: 500x500x600)

- 5-axis milling machining center Grob G 550 Generation 1 with robot cell for pallets, parts and tool handling (component dimensions: 800x700x600)

- 5-axis milling machining center DMG DMF 260 (component dimensions: 2600x1100x1000)

Measuring:

- Zeiss Contura with Vast Gold measuring head (component dimensions: 800x700x600)

- Faro EDGE Measuring system with 3D scanner

- Tool presetter Zoller Smile Pilot 3

Washing:

- Kärcher parts washer PC 60/130 T

- Ultrasonic cleaning device Desonic UL 45

3D print / 3D scan:

- DMG LASERTEC 30 DUAL SLM

- Zeiss T-Scan Hawk 2

Lathing:

- Alpha 350T